A unique manufacturing process

Thanks to our expertise, we have been able to develop a new method of bending steel and alloys that opens up possibilities that were unthinkable until now.

- Production of different designs with progressive features.

- Crystalline structure with linear orientation in the spring and asymmetric structure levels in terms of orientation and density.

- Improvements to the energy storage capacity of various products (such as springs, instruments and implants).

- Possibility of manufacturing articular implants that do not wear.

- Orthopaedic plates with variable flexibility.

WA design – Swiss Made

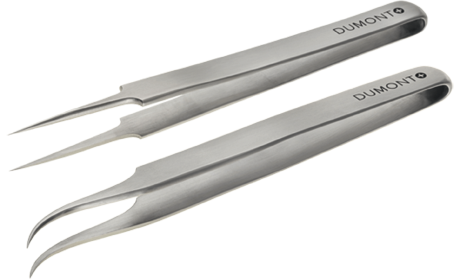

Introducing a new tweezer design

Straight from our workshops and laboratory, our new WA tweezers have been designed to resolve an issue that is particularly problematic in the medical field. A long-ignored problem, biofilm on tweezers or forceps can cause many infectious diseases. After more than 5 years of research and development, we have developed a new tweezer design that offers the following advantages:

- Finer tips for greater precision and improved stability thanks to our expertise in working with steel.

- A domed end that allows instruments to be thoroughly and easily cleaned. No soldering grooves to prevent biofilm residues.

- A surface that is dirt and corrosion-resistant thanks to a unique nanocrystallisation process.

- Pressure remains constant, allowing the user to carry out more delicate work without becoming tired.

- • Improved ergonomics – the WA design fits snugly in the hand.

New WA tweezers, types 5 et 7

Our new WA tweezers will soon be available for all sectors.